Maintenance Types

As one of the definitive providers of performance chemicals in the nation, Anion understands that the backbone of your business relies upon your machinery's ability to withstand internal irritants, operational wear and tear, and heat transfer surface efficiency. That is why we built our business upon three rock solid foundations that give your business machinery's the stability it needs to remain functioning at optimal levels.

The 3 Foundations of Machinery Stability

The First Foundation: Plant Preventive Maintenance

Utilizing a preventive maintenance plan to protect your machinery's metal parts from micro-pitting and excessive wear can literally save your business hundreds of thousands of dollars in breakdown maintenance costs and lost production time. That is why we partnered with the best preventive maintenance provider in the industry, Nexolub, to provide you with unsurpassed mechanical component protection that can:

- ensure the mechanical stability of your equipment indefinitely

- recondition micro-pitted and worn metal surfaces into their original smooth condition

- lower the vibration and temperature of your machinery to significantly improve performance

Troubleshooting Protocols Click Here For Our Kiln Maintenance Daily, Weekly, Monthly & Yearly Protocols

The Second Foundation: Plant Predictive Maintenance

Now that we have provided the best possible option to protect your machinery's vital metal surfaces from unnecessary wear and tear, Anion is also here to help your business ensure essential plant predictive maintenance. Due to its inherent design configuration, the plane of your kiln's tires can shift from a perpendicular to a horizontal position, causing the tire's rotation to differ from the shell's rotation. This in turn causes the tire creep, tire boar wear, high shell ovality and refractory failures that decrease your business's production time and ultimately cost you thousands of dollars in kiln breakdown maintenance costs. Luckily, Anion's two premier kiln predictive maintenance products, SlickBar and Slick-Spray:

Now that we have provided the best possible option to protect your machinery's vital metal surfaces from unnecessary wear and tear, Anion is also here to help your business ensure essential plant predictive maintenance. Due to its inherent design configuration, the plane of your kiln's tires can shift from a perpendicular to a horizontal position, causing the tire's rotation to differ from the shell's rotation. This in turn causes the tire creep, tire boar wear, high shell ovality and refractory failures that decrease your business's production time and ultimately cost you thousands of dollars in kiln breakdown maintenance costs. Luckily, Anion's two premier kiln predictive maintenance products, SlickBar and Slick-Spray:

- protect your low and high-temperature operating kilns from increased friction

- maximize kiln protection from cold welding and galling

- triple the lifespan of your kiln's tire support pads

- save your business up to $50,000 in support pad replacement

The Third Foundation: Plant Proactive Maintenance

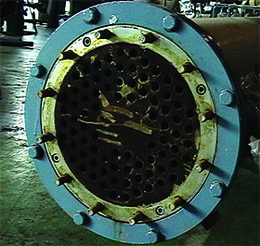

It's a fact: Internal irritants are going to find their way into your machinery. Although water scale and limescale are the usual culprits, other types of scale might also infect your machinery, and reduce your machinery's heat transfer capabilities while increasing your energy and production costs. However, you can control limescale and water scale intrusion with regular use of Anion's D'Scale. Our time-tested proactive maintenance products remove internal irritants without the hassle of having to disassemble and reassemble your machinery. We offer three unique products to accommodate your business's needs:

- Anion DeScale General Liquid Descaler

- Anion DeScale Stainless

- Anion Eco Safe D'Scale

We Can Help You Minimize Breakdown Maintenance

We take a sincere interest in helping our customers. We bring valuable information and news, including ways to optimize plant operating capabilities.

We realize this goal each and every day by providing the best possible alternatives to breakdown maintenance available on the market. Get in touch with us to discover how your business can benefit from preventive, predictive and proactive maintenance, and avoid the pain of expensive breakdown maintenance. Our skilled, knowledgeable representatives can help you develop a preventative maintenance plan that can improve machinery reliability and cost control efforts.

Request More Info

Find out how our products can help you move to a more proactive form of maintenance for your plant.

We are a global lubricants supplier