Kiln Tire/Shell Interface Lubricant

Alternative solution for high temp maintenanace challenges

Learn more about our other kiln lubricant products >>

Trunnion Bearing Fluid | Dry Graphite Lubricating Blocks | SlickBar ® Solid Lubricating Bars

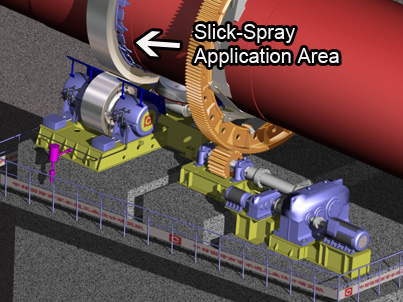

Anion understands that for kilns with extremely high temperatures, sometimes a liquid spray with a long applicator wand is the more desirable application method. Anion Slick-Spray is a highly effective, non-flammable kiln tire spray lubricant and is the proven answer to this problem.

Why Our Tire Spray Lubricant is Superior

High-temperature tire creep, the distance the kiln shell moves relative to the tire each kiln revolution, results in a horizontal motion that naturally elevates the pressure on your kiln's tire stop blocks. This pressure can cause:

- friction between your kiln's tire ID and its support pads

- higher shell ovality degradation rate

- expensive support pad replacement

- hundreds of thousands of dollars in unexpected maintenance costs and lost production time

Slick-Spray ™: Anion's Plant Preventive Maintenance Answer

Fortunately, Anion's plant predictive maintenance product line includes Slick-Spray™, an exceptional kiln tire spray lubricant that is the only one of its kind to exhibit intermolecular attraction properties. Slick-Spray™ provides premium metal adhesion and greater load carrying characteristics than any other liquid support pad lubrication available on the market. Best of all, Slick-Spray™ is easy to apply with a small, pressurized sprayer outfitted with an articulated spray nozzle.

Slick-Spray ™: For Kiln Preventive Maintenance

Find out how easy it is to let Slick-Spray deposit a solid, slick coat onto the surface of your tire bore and kiln support pad’s outside diameter. Once applied, Slick-Spray™ will grant your kiln maximum protection from galling and cold welding. Slick-Spray's soft metal solids quickly fill your kiln's surface imperfections, which in turn:

- reduces friction

- increases the potential to easily triple the lifespan of your kiln's tire support pads

Contact Anion Specialty Chemicals today to schedule your own Slick-Spray kiln maintenance plan proven to maximize your bottom line through decreasing your kiln's support pad wear and reducing its retainer pressure.